The artisans at Laura Zindel Design create small batch handcrafted ceramic tableware and gifts. Each of us brings a unique skill set of artistry and craftsmanship making what we do every day, a recipe of many hands.

Drawing

Drawing

Our process begins with Laura’s original graphite pencil drawings of Flora and Fauna. Each collection is researched and inspired by a wide variety of sources and imagery before the pencil hits the paper.

Our tableware is a celebration of nature, curiosity and wonder. Laura’s wish is for her collectors to be able to curate from her menagerie their own personal cabinet of curiosities… and put their story on the table.

Fabrication

Fabrication

Our products come in a wide range of shapes and sizes. We use both slip cast and ram press fabrication techniques. Each piece is fabricated using the method best suited to the product.

Ram Pressing

All of our handmade work is fabricated using white earthenware clay mixed for us by a local New England clay maker. Before we begin Ram pressing to create platters, serving dishes and bowls, wet clay is prepared by being weighed and cut to the proper size for each product. Hundreds of pressings can be done in a day.

The clay is pressed between the upper and lower dies with tons of hydraulic pressure. The wet piece is released from the upper die by compressed air pressure pushed through a network of internal valves built inside the die.

After the pressed piece is released it is smoothed with a sponge and prepared for the trimming process. For every hour of Ram pressing it takes an additional 2-3 hours of trimming and finishing before the piece is dried and bisque fired.

Mold Making

We make all the molds for our handmade products in our studio. For slip casting a rubber mother mold is made from a prototype.

Multiple plaster production molds are then made from the rubber molds.

Ram Press dies are made of a dense cement / plaster with a high crushing strength and poured into a steel casing. Each die set weighs 200-500 pounds and is put on the press with a fork lift. Each die can take 20 hours or more to complete due to the complex internal structure that is is built inside the die to channel compressed air through a fine network of pores.

Slip Casting

Slip is a liquid clay body that is poured into a soft porous plaster mold. The water in the slip is absorbed by the plaster walls creating a clay shell. Each piece is timed so that the wall develops to the proper thickness before the slip is poured out and reconstituted.

When the clay piece is dry enough the molds are taken apart and the form is gently removed.

Slip cast forms are slowly dried until they are firm enough to be trimmed.

Trimming

Once removed from the plaster production mold, clay seams and funnels are removed and edges are smoothed with a wet sponge.

Our logo is stamped into the bottom of each piece. The ware is then slowly dried on racks before it is placed in the kiln to be bisque fired.

Glazing

After the first firing, bisqueware is inspected for flaws and prepared for the glazing process.

A layer of black underglaze is applied to the carved lines that frame the front and back and the pressed branding stamp. Underglaze is then wiped away with a wet sponge to highlight the lines and logo.

Each piece is brushed with 3 coats of our signature hand mixed glazes. Our glazes are made from our own recipes that are developed in house.

Decorating

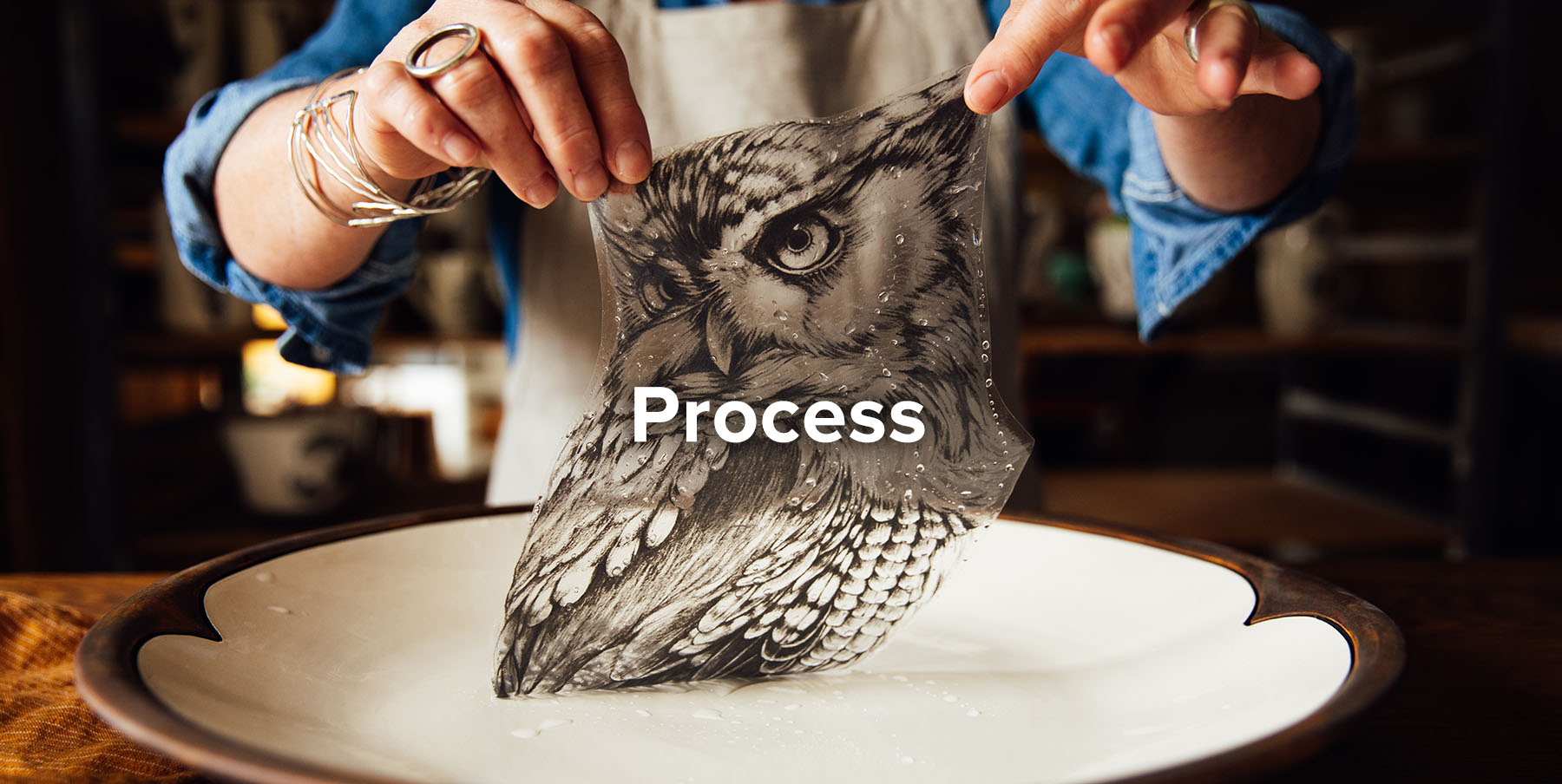

Laura’s graphite pencil drawings are first scanned and digitized. The images are silk screened and printed with enamel to create a ceramic transfer. All of our transfers are made in France. Transfers are then gathered and cut out to be prepared for each order.

The transfers are soaked in water to remove the paper backing and placed onto the glazed ceramic surface.

Each transfer is pressed onto the glazed surface, squeegeed and dried in place.

The finished piece is then fired in the 3rd and final firing. Just as the glaze begins to melt, the kiln is shut off. The organic clear coat burns away and the image melts permanently to the surface of the glaze.

Each Piece is Unique

Final Firing: After the 3rd and final firing each finished piece is removed from the decorating kiln and carefully inspected for flaws.

Everything we make is handmade to order and we do not carry stock. By the time we ship your order every single person on our staff has touched your unique piece multiple times to insure that it is perfect before it goes into a box.

Last but not least, your order is carefully packed for shipping from our studio to arrive safely at your doorstep.